Cuomo-Method¨

With the natural and patented Cuomo Method it is possible to monitor the physical and chemical condition during the transformation process (bacterial alterations, acidification, pH). It’s a method for controlling, analyzing and managing phases of conservation and/or processing of food in a mobile or fixed closed space. This method communicates scientifically and directly with food, reproducing a series of microclimates that are ideal for the processing of cured meats, salami, fish and cheese in the traditional way.

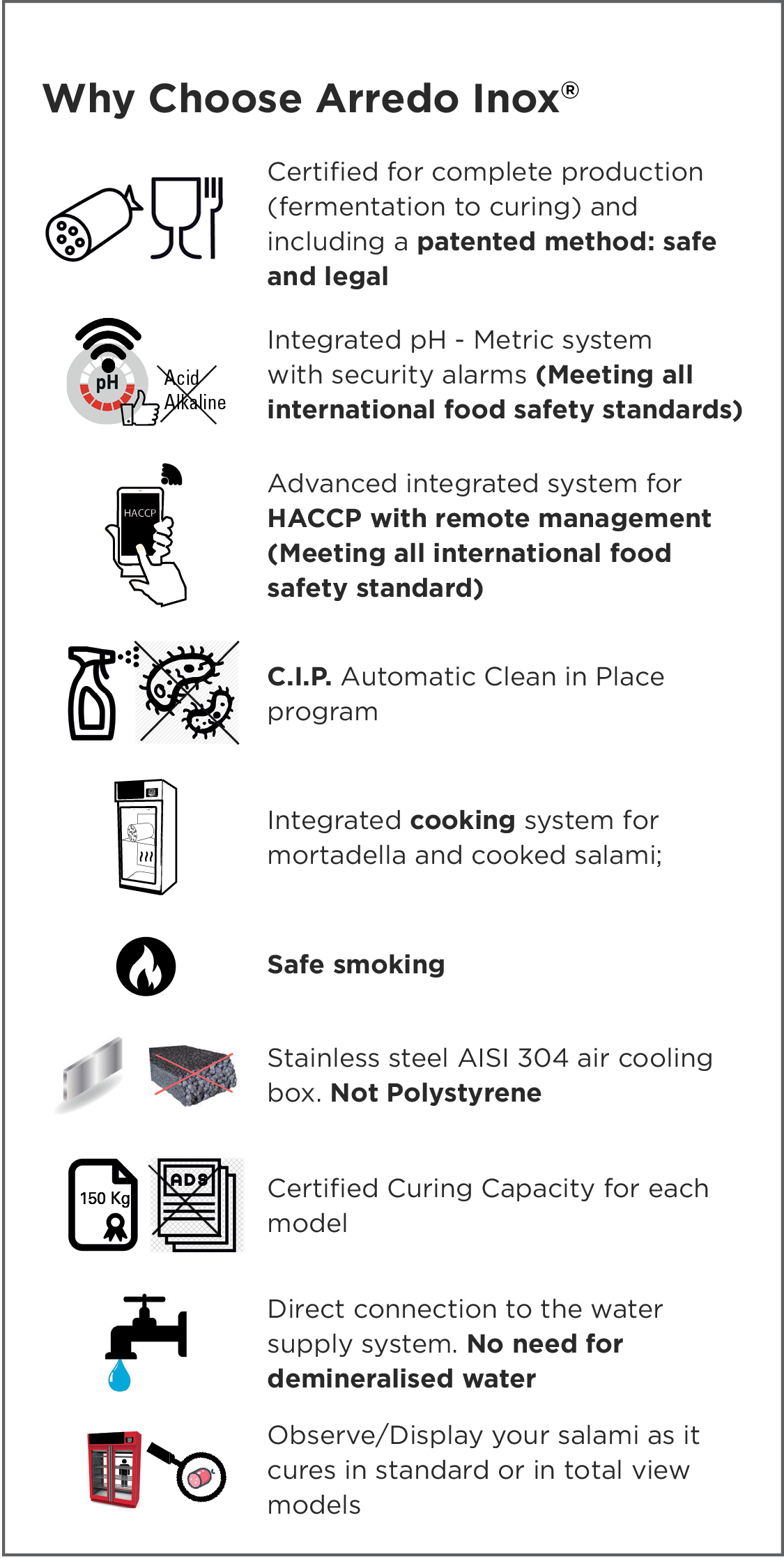

DECLARATION OF CONFORMITY of the device and a patented method n° 1408549 for controlling and managing the maturation/the curing/the seasoning of food in a closed environment

Not just a fridge

Ventilation and air circulation inside the unit is necessary to avoid the formation of pathogen microorganisms, as well as the proliferation of molds. It also supports a better result in organoleptic (such as taste, color, odor, and feel), helping the process of uniform transformation.

Temperature -Temperature is essential for the enzymatic processes. Just temperature control is not sufficient without a correct management of this parameter.

Humidity -Water and consequently the humidity are undoubtedly a key element for the correct food transformation process. Humidity is responsible for the microbiological status of food. It should be managed, controlled and corrected. with the patented Fumotic¨ system

Sicur Food Control¨ is a programmable control system (touch screen), provided with a software entirely dedicated to food processing. Very intuitive and easy to use, thanks to its large LCD display, ClimaTouch¨ automatically manages the sequential control of all the stages of maturation, curing and seasoning with measurement of fermentation processes with pH probe

Integrated pH Control System dedicated to reading pH levels during transformation processes monitoring the fermentation and the acidification. With pH control you have an HACCP monitoring system evolved to meet all international stand.

C.I.P (cleaning in progress). The machine is equipped with a washing program. HACCP Integrated data tracking management with optional remote management capabilities